sa a370 impact test|a370 standard pdf : importing %PDF-1.5 %¡³Å× 1 0 obj >/ProcSet[/PDF/Text]>>/Type/XObject/BBox[ 0 0 595 839]/Length 20/Matrix[ 1 0 0 1 0 0]/Filter/FlateDecode>>stream xœ3T0BC0™œ«P¨ ò d . 21 de jan. de 2021 · Delivering what the players want is what Felix Gaming is all about » We will help you find the best real money casinos to go with your favourite online slots.

{plog:ftitle_list}

17 de abr. de 2023 · Kemono Party and Coomer Party may seem like two sides of the same coin, but they are quite different. While both involve animal-themed art and costumes, Kemono Parties focus on creativity and self-expression while Coomer Parties have a more sexualized aspect to them.

Hardness Test: Brinell test, Rockwell test, Portable hardness test. Charpy V-notch impact test: general process, significance and use, apparatus, sampling and number of specimens, . ASTM A370 is expansive, covering tests like Tension, Bend, Hardness, Brinell, Rockwell, Portable, and Impact, each catering to distinct aspects of mechanical property .

Motorized Impact Testing System (MPX) Available in capacities from 300 to 900 joules, the Instron MPX Series of motorized pendulum impact testers are preferred for metals impact testing to Charpy and Izod standards.%PDF-1.5 %¡³Å× 1 0 obj >/ProcSet[/PDF/Text]>>/Type/XObject/BBox[ 0 0 595 839]/Length 20/Matrix[ 1 0 0 1 0 0]/Filter/FlateDecode>>stream xœ3T0BC0™œ«P¨ ò d .This standard is issued under the fixed designation A370; the number immediately following the designation indicates the year of original adoption or, in the case of revision, the year of last .

Standard Test Methods and Definitions for Mechanical Testing of Steel Products 1 This standard is issued under the fixed designation A370; the number immediately following the .ASTM A370 is the most used standard for measuring the toughness of metal samples. Testing is typically undertaken at room temperature, and also at -50degC for many grades, to align to common industry standards such as .Tensile Testing: Evaluates the material’s strength and ductility under uniaxial tensile stresses. Bend Testing: Assesses the flexibility of the material. Hardness Testing: Measures the material’s resistance to deformation. Impact Testing: .

These test methods describe procedures for testing the mechanical properties of multi-wire steel prestressing strand. These test methods are intended for use in evaluating .Recognize the various tension test specimen types and the ASTM A370 guidance for preparation of these specimens to their applicable dimensions and tolerances. Describe the determination .ASTM A370 also includes Charpy impact test method requirements but focuses only on steel products. All three standards provide details for properly measuring the energy absorbed by the notched specimen when impacted by a swinging .

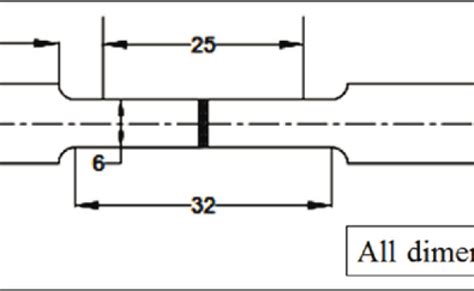

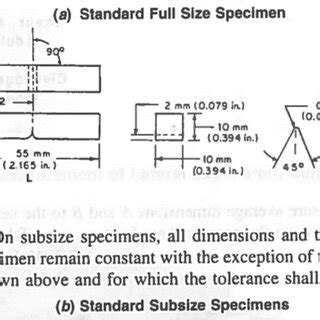

According to ASTM A370,the standard specimen size for Charpy impact testing is 10 mm × 10mm × 55mm. Subsize specimen sizes are: 10 mm × 7.5 mm × 55mm, 10 mm × 6.7 mm × 55 mm, 10 mm × 5 mm × 55 mm, 10 mm .

astm a370 specs

The ASTM A370 testing standard outlines the procedure needed to evaluate the ductility and strength of steel materials. To begin the process, technicians measure the sample’s dimensions and note the material’s smallest cross-sectional area before placing gage marks throughout the material at a predetermined gage length.WHAT IS ASTM A370? ASTM A370 is a crucial standard in the realm of mechanical testing, specifically designed for assessing the properties of steel, stainless steel, and related alloys. This standard outlines test methods and definitions for various mechanical tests, including tension testing, impacting its significance on the quality evaluation of materials used in construction .Charpy Impact Testing. Charpy impact tests are routinely undertaken during the production of metals. ASTM A370 is the most used standard for measuring the toughness of metal samples. Testing is typically undertaken at room temperature, and also at -50degC for many grades, to align to common industry standards such as Norsok M-001.3.3 Definition of Terms Specific to the Procedure for Use and Control of Heat-cycle Simulation (See Annex A9): 3.3.1 master chart, n—a record of the heat treatment received from a forging essentially identical to the production forgings that it will represent. 3.3.1.1 Discussion— It is a chart of time and temperature showing the output from thermocouples imbedded in the forging .

ASTM A370 is a testing standard that covers the mechanical testing definitions and procedures of steel products such as wrought and cast steels, stainless steels, and related alloys. . ADMET universal testing machines conform to the requirements of Practices E4 and can be used for A370 tension and bend testing. Hardness and impact tests will .E23 Test Methods for Notched Bar Impact Testing of Me-tallic Materials E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications E83 Practice for Verification and Classification of Exten-someter Systems E110 Test Method for Rockwell and Brinell Hardness of Metallic Materials by Portable Hardness Testers

1.1 These test methods 2 cover procedures and definitions for the mechanical testing of steels, stainless steels, and related alloys. The various mechanical tests herein described are used to determine properties required in the product specifications. Variations in testing methods are to be avoided, and standard methods of testing are to be followed to .

ASTM International - ASTM A370-20 Standard Test Methods and Definitions for Mechanical Testing of Steel Products inactive Buy Now. Details. History . Ductile vs. Brittle Behavior—Body-centered-cubic or ferritic alloys exhibit a significant transition in behavior when impact tested over a range of temperatures. At temperatures above .Not fewer than two tensile tests and two impact tests are required for each lot containing 20 000 lbs [9000 kg] or less. Every additional 10 000 lbs [4500 kg] or fraction thereof requires an additional tensile test and impact test. 6.1.2.2 For studs, bolts, screws, etc., one tension test and one set of three impact specimens shall be made for eachDesignation: A370 – 11 Standard Test Methods and Definitions for Mechanical Testing of Steel Products. Omid Beygi. See full PDF download Download PDF. Related papers. Standard Test Methods and Definitions for Mechanical Testing of Steel Products 1. a b.This standard is issued under the fixed designation A370; the number immediately following the designation indicates the year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of

ASTM A370 is one of the most broadly recognized and encompassing standards for measuring the tensile strength of metals.This guide is designed to introduce you to the basic elements of an ASTM A370 tensile test and provide an overview of the testing equipment, software, and specimens needed. In addition to tension tests, the standard also outlines charpy impact, .About the Subject Matter Expert. Shawn Byrd, as technical manager at Tinius Olsen Shawn's primary focus is on materials testing and the application of various standards using different testing platforms to assist in the evaluation of materials and products.Shawn is a member of the following ASTM International Committees, A01 on Steel, Stainless Steel and related Alloys, . ASTM International - ASTM A370-17a Standard Test Methods and Definitions for Mechanical Testing of Steel Products inactive Buy Now. Details. History . Ductile vs. Brittle Behavior—Body-centered-cubic or ferritic alloys exhibit a significant transition in behavior when impact tested over a range of temperatures. At temperatures above .cation SA-370 in Section II of that Code. 3 Annual Book of ASTM Standards, . E 23 Test Methods for Notched Bar Impact Testing of Metallic Materials6 . A370–03 3 NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

An impact test is used to determine a material’s impact strength, or the material’s ability to resist deformation when subjected to a sudden shock or impulse load. . ASTM A370, and ASTM D256 govern the exact testing procedure and test specimen requirements for each type of impact test, and for different material groups (e.g., metals vs . This document discusses impact testing procedures according to ASTM A370 and E-23 standards. It describes the apparatus, testing procedures, significance, and interpretation of results for Charpy impact testing. . The impact test shows somewhat higher energy absorption values than the static tests above the transition temperature and yet, in .

Designation: A370 – 11 Standard Test Methods and Definitions for Mechanical Testing of Steel Products Omid Beygi download Download free PDF View PDF chevron_rightThe flanging test to ISO 8494, DIN 50139, ASTM A370 is a test method in which the end of a tube is bent by 90°. The test determines, through plastic deformation, whether tubes are suitable for flange formation. . Flexure Test ISO 178; Impact Tests; S-N test DIN 50100; ILSS; Tensile Strength; Yield Point; News & Events. testXpo; Digital .ASTM A370-12 Standard Test Methods and Definitions for Mechanical Testing of Steel Products. . Impact: 19 to 28: Keywords: 29: 1.3 Annexes covering details peculiar to certain products are appended to these test methods as follows: Annex: Bar .Along with tensile testing, impact testing is also specified under ASTM A370 and is further specified under other impact testing procedures. Specifically, ASTM E23 which includes both Charpy and Izod test procedures for steel. Hardness testing is the final specification for mechanical testing that is described under A370.

In our July 2012 issue we discussed “ASME Section VIII UHA-51 Impact Test: Changes Affecting Cryogenic Vessels Made from Austenitic Stainless Steel”. This article prompted an email last month from reader Walter Detlef of Linde – Kryotechnik. In his email, Walter made assertions that raised two interesting questions not covered in the original article. Find the most up-to-date version of ASTM A370 at GlobalSpec. UNLIMITED FREE ACCESS TO THE WORLD'S BEST . 2 For ASME Boiler and Pressure Vessel Code applications see related Specification SA-370 in Section II of that Code. Document History . These test methods describe notched-bar impact testing of metallic materials by the Charpy (simple .

2 For ASME Boiler and Pressure Vessel Code applications see related Specification SA-370 in Section II of that Code. . E23 Test Methods for Notched Bar Impact Testing of Metallic Materials . A370 − 12a 2 L7HK6 WDQGDUGV KWWSV VWDQGDUGV LWHK DL cation SA-370 in Section II of that Code. . E23 Test Methods for Notched Bar Impact Testing of Me-tallic Materials E29 Practice for Using Signi®cant Digits in Test Data to Determine Conformance with Speci®cations . A370 þ 23 2. 3.2.6 transition temperature, nÐfor speci®cation purposes, .

astm a370 requirements

20 de dez. de 2023 · O filme encerrará o universo de heróis no cinema com aventura divertida, mas nada memorável. Saiba mais sobre a trama, os efeitos e a direção de .

sa a370 impact test|a370 standard pdf